Ginni Filtration, yet another venture of Ginni Filaments Limited, is committed to deliver the world class products. Understanding the latent need of purification, the group has diversified into the filtration segment with an objective to innovate, research, formulate ideally customize product as per the need of Indian water treatment industry with the focus to minimize wastage of water in the name of filtration.

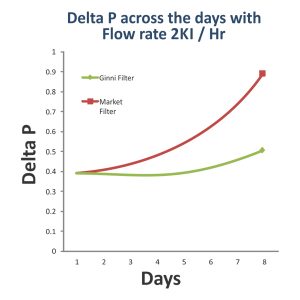

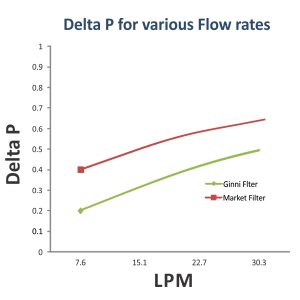

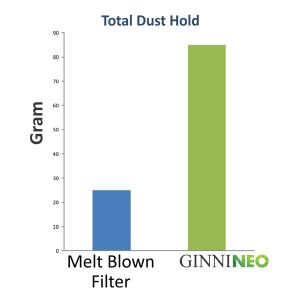

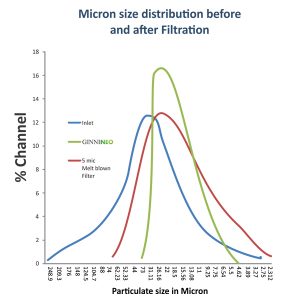

Ginni NEO filters are designed for removal of contaminants from water and other liquids. Due to its novel gradient design and high void volume, It has high filtration efficiency, extremely high dirt holding capacity as well as good retention capability of the contaminants along with low pressure drop.

As the Filter Media is of PET, so apart from Water, it has high suitability in the area of Petroleum oil, edible oil and acid solution and in high temperature filtration. As there is no chemical inside, so can be safely used in Pharma, Cosmetic, Biotechnology industry as well as in other industries.

Depth Cartridge Filter

Ginni Neo Depth Filter, India ‘s first customized dual filter, it has capacity to de-contaminate both Water & Oil with High efficiency and retention capacity. Made in India from world class standard of Spunlace. Developed in the state of the art plant, equipped with the converting facility to deliver as per the customized need. Unique PET Media filter withstands temperature above 100 c makes it ideal for water treatment industry, Pharma industry, Cosmetic Industry & Bio- technology industry.

Reverse Osmosis Membrane

Ginni Neo RO Membranes is world’s finest product coupled with advanced membrane technology that yields product of the highest quality, stable performance, uniquely engineered to have a high level of salt rejection. Ginni Neo Membranes have higher design flux, high chemical and mechanical resistance, high fouling resistance, high resistance to organic contamination, higher mills spacer & long service life. Our membranes have higher TDS rejection properties and removes, high molecular-weight substances, colloidal materials & organic and inorganic polymeric molecules.

Ultra Filtration Membrane

Ginni Neo UF Membrane is hollow fiber, inside-out based technology, capable of removing higher suspended solids, colloidal materials, and organic & inorganic polymeric molecules. It is used for water & TSS separation process with pore sizes in the range of 0.01 to 0.001 micron.

- Higher design flux

- High chemical & mechanical resistance

- High fouling resistance

- High hydrophilicity excellent clean ability

- Wide range of MWCO

- High chlorine tolerance design

- Long service life, low pressure